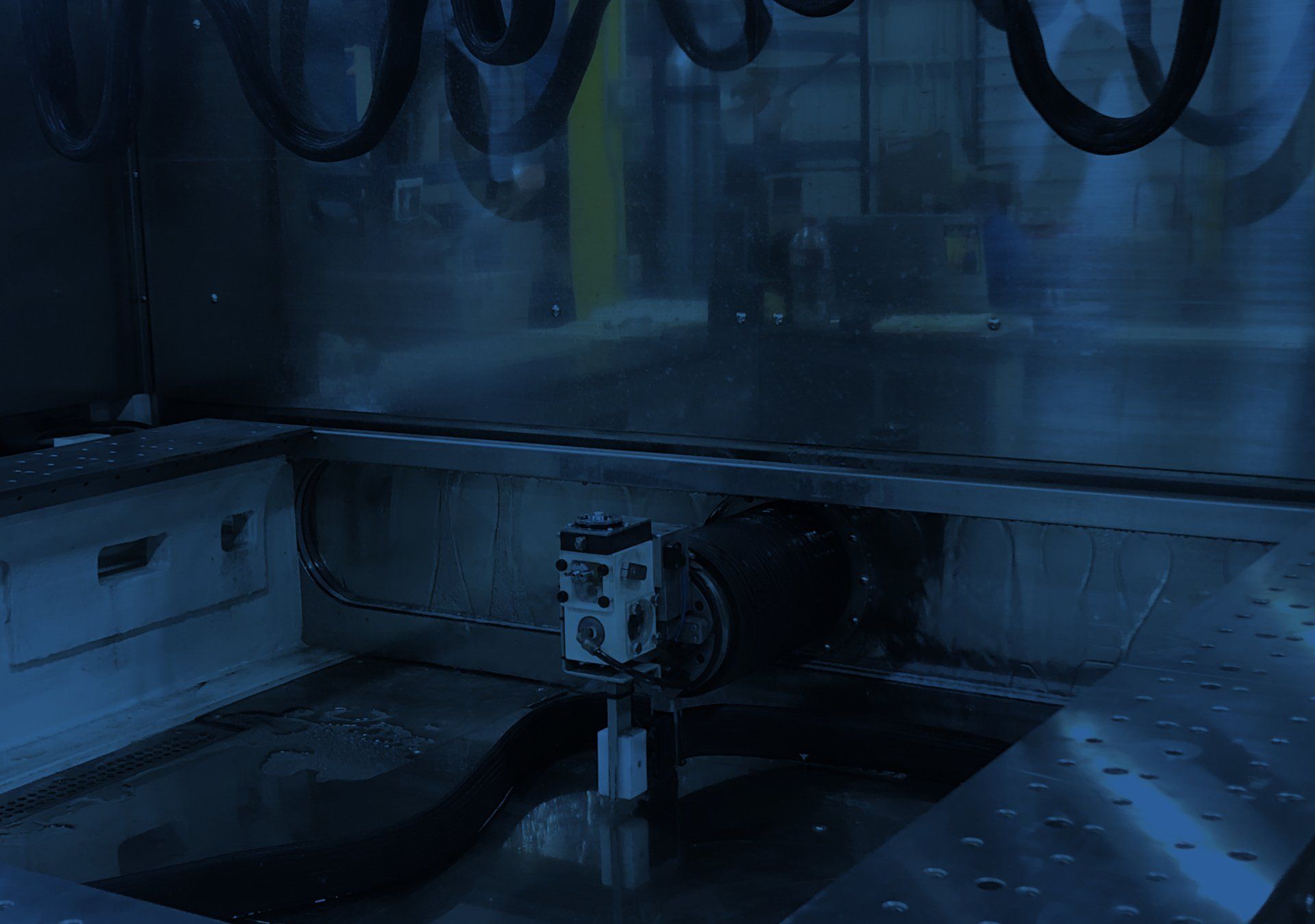

The Value of Waterjet Cutting

CERTIFICATIONS

View All Certifications

Benefits of Water Jet Cutting

Waterjet Cutting creates superior edge quality

- Typical finishes 125-250 microns – Q1 through Q5

- Dependent upon materials and thickness

- Reduced need for secondary finishing

- No cutter-induced distortion

- Low cutting forces on workpiece

- Limited tooling requirements

- Little to no cutting burr

- Small kerf size (.020″-.045″) reduces material scrap

Waterjet Cutting preserves metallurgical integrity

- No heat-affected zone

- Localizes structural changes

- No cutter-induced metal contamination

- Eliminates thermal distortion

Waterjet Cutting can perform composite cutting – nonmetallic

- Minimal delimitation of edge cut surfaces

- No fraying of edge cut surfaces

- No thermally induced cracking

- No splintering

Waterjet Cutting creates smooth cuts

- No slag or cutting dross

Waterjet Cutting is omni-directional

- Precise multiplane cutting of contours, shapes, and bevels of any angle

Limitations of Waterjet Cutting

- Cannot drill flat bottom, “non-through” holes

- Cannot cut materials that degrade quickly with moisture

- Surface finish degrades at higher cut speeds, which are frequently used for rough cutting