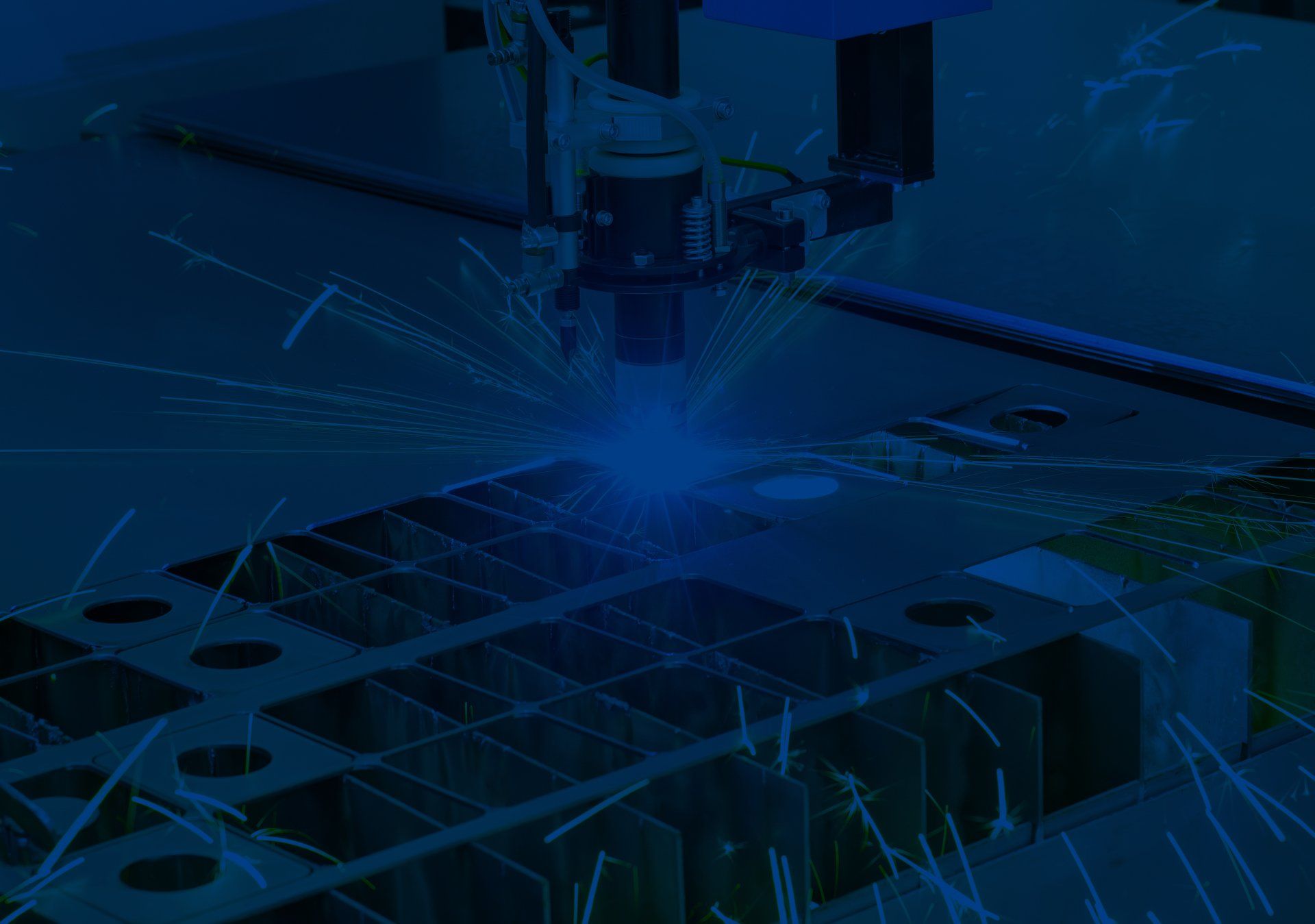

Electron Beam Welding Services

EBTEC offers our customers a partnership in component fabrication by solving their complex joining need with EB Welding.

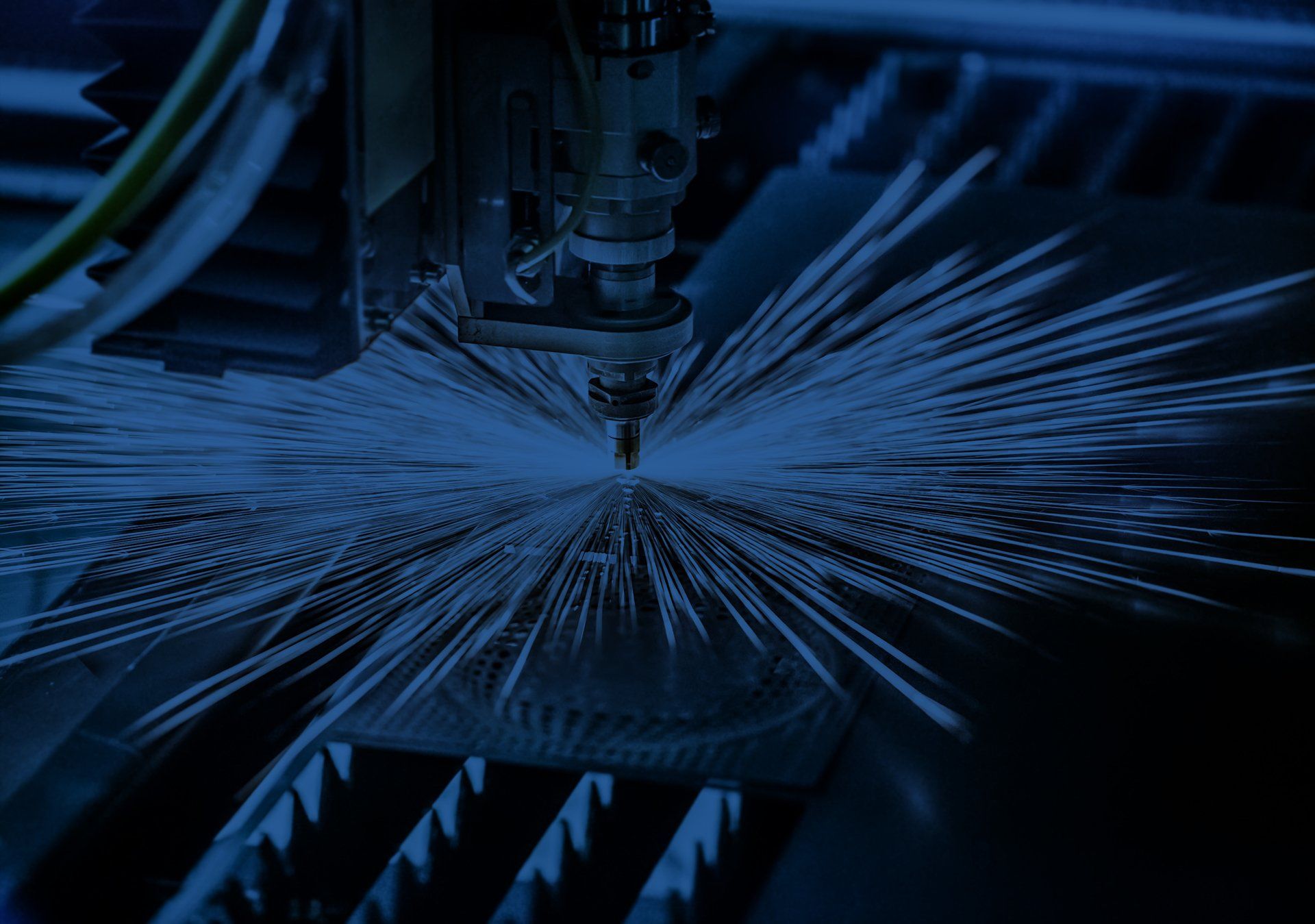

Our electron beam welding capabilities include 11 EB welding machines with depth-to-width ratios up to 30-1 with minimum distortion. Weld depths can range from .002″ depth to 3.00″ and we are able to accommodate pieces up to 10 feet in diameter. Many of our welding machines have CNC controls that allow for precise and consistent weld repeatability on complex weld paths.

EBTEC has over 50 years of high-energy beam experience. We are conveniently located in East Windsor, CT, with easy on and off to Rt. 91, and operate in a newly-updated 83,500 square foot manufacturing space with two, 10-hour shifts. Our focus is on quality processes and on-time delivery (OTD> 90%) to meet all of our customers' requirements.

EBTEC utilizes advanced welding technologies and processes, providing cost-effective services to most of the largest companies in the Aerospace, Power Generation, Industrial, Defense, and Medical industries. We also are pleased to serve many of the 2nd and 3rd-tier suppliers with our services. Our shop is typically filled with aircraft engine parts and turbine parts for companies like GE, PWA, Rolls Royce, Honeywell, Lockheed Martin, and Siemens Energy. Whether an application is in development, a prototype, a single part flow, or high volume, a highly-experienced operator with years of professional training will be caring for your valuable assets as we perform each of your welding services.

EBTEC maintains an AS9100/ISO9000 certification and NADCAP welding certification and can also provide all your non-conventional cutting, coating services. With more added value and a vertical supply chain, EBTEC’s make to print solution may also be of interest.