The Value of Electron Beam Welding

CERTIFICATIONS

View All Certifications

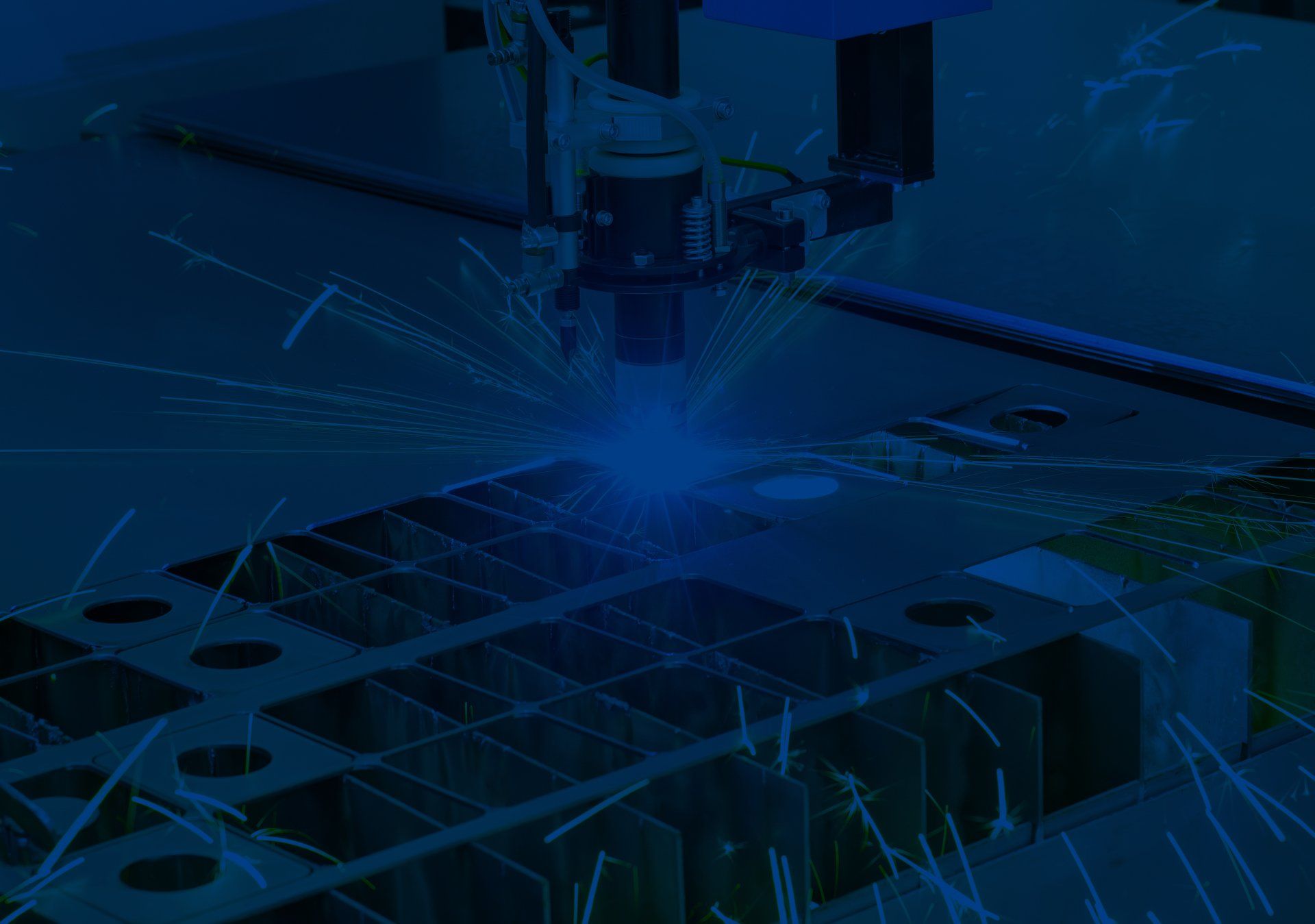

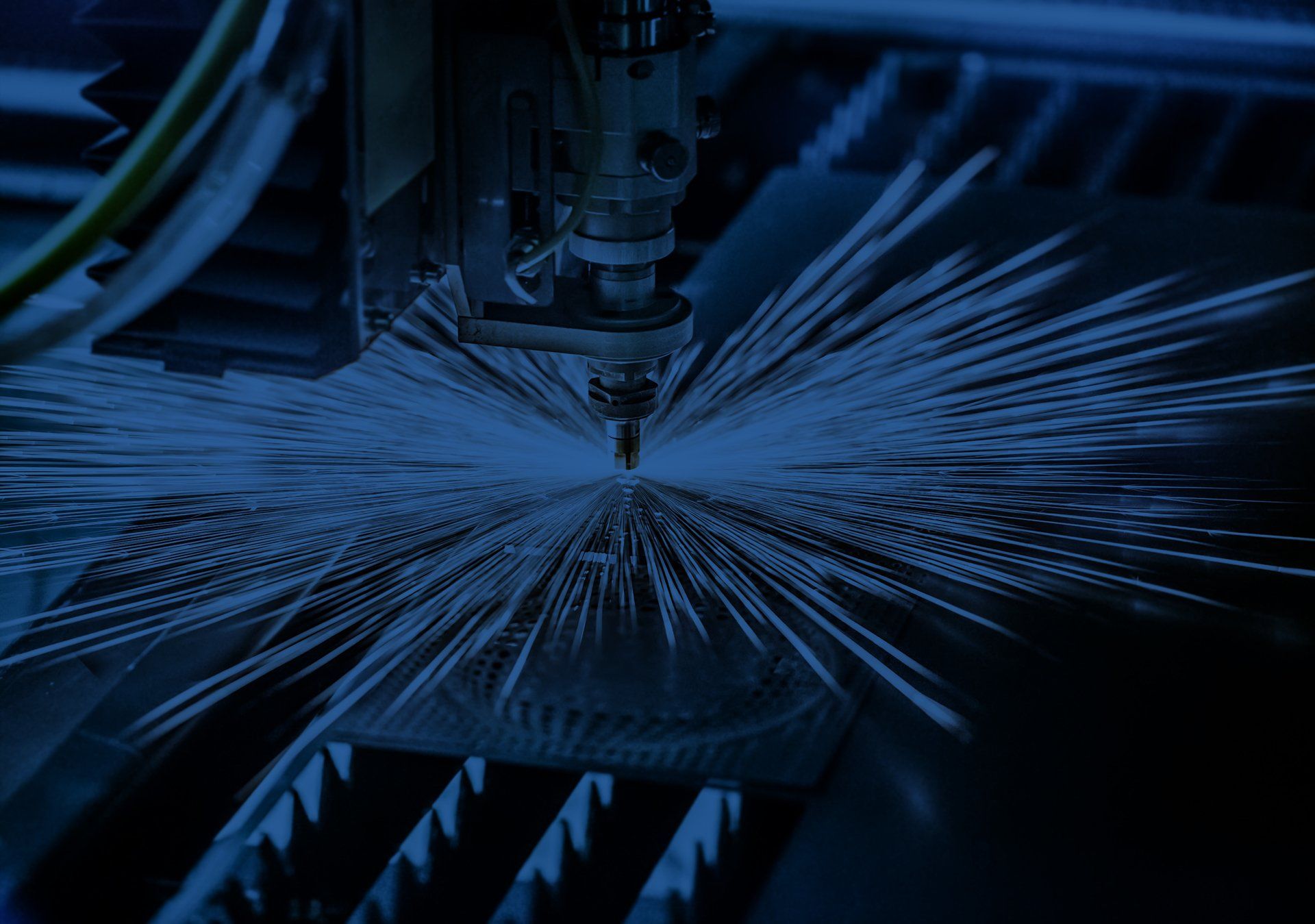

The Benefits of EB Welding

- Receive the maximum amount of weld penetration with the least amount of heat input, resulting in reducing distortion

- EB Welding often reduces the need for secondary operations

- Highly repeatable through digital control and frozen processes

- A cleaner, stronger, and homogeneous weld is produced in a vacuum

- The electron beam machine’s vacuum environment eliminates atmospheric contaminants in the weld

- Exotic alloys and dissimilar materials can be welded

- Extreme precision due to CNC programming and magnification of operator viewing

- Electron Beam Welding frequently yields a 0% scrap rate

- The electron beam process can be used for salvage and repair of new and used components

The Limitations of EB Welding

- Evacuation time – creation of vacuum environment – EBTEC remediates this with high pump down speeds and greater part densities with tooling into each cycle

- High Capital Costs – with 11 electron beam machines on premise, EBTEC mitigates that Capital Expense to place equipment within your facility

- Work Chamber size restraints – with 11 machines varying from 1 cubic-foot to 1404 cubic-feet, EBTEC has a machine that fits your specific needs.