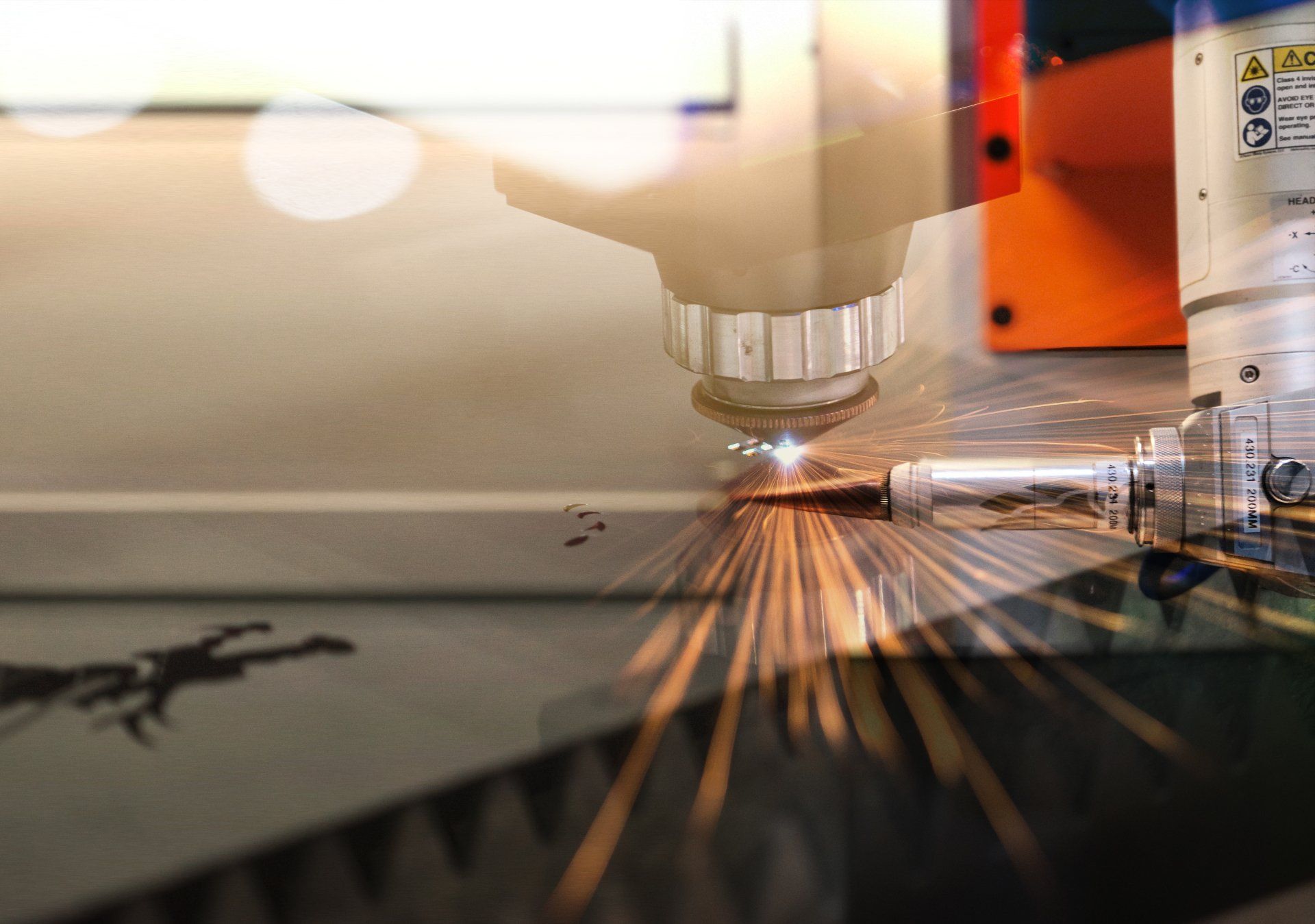

Laser Cutting Services

EBTEC Corporation is a leading supplier in the US laser cutting industry serving; Aerospace, Medical, Power Generation, and Industrial markets.

CERTIFICATIONS

View All Certifications

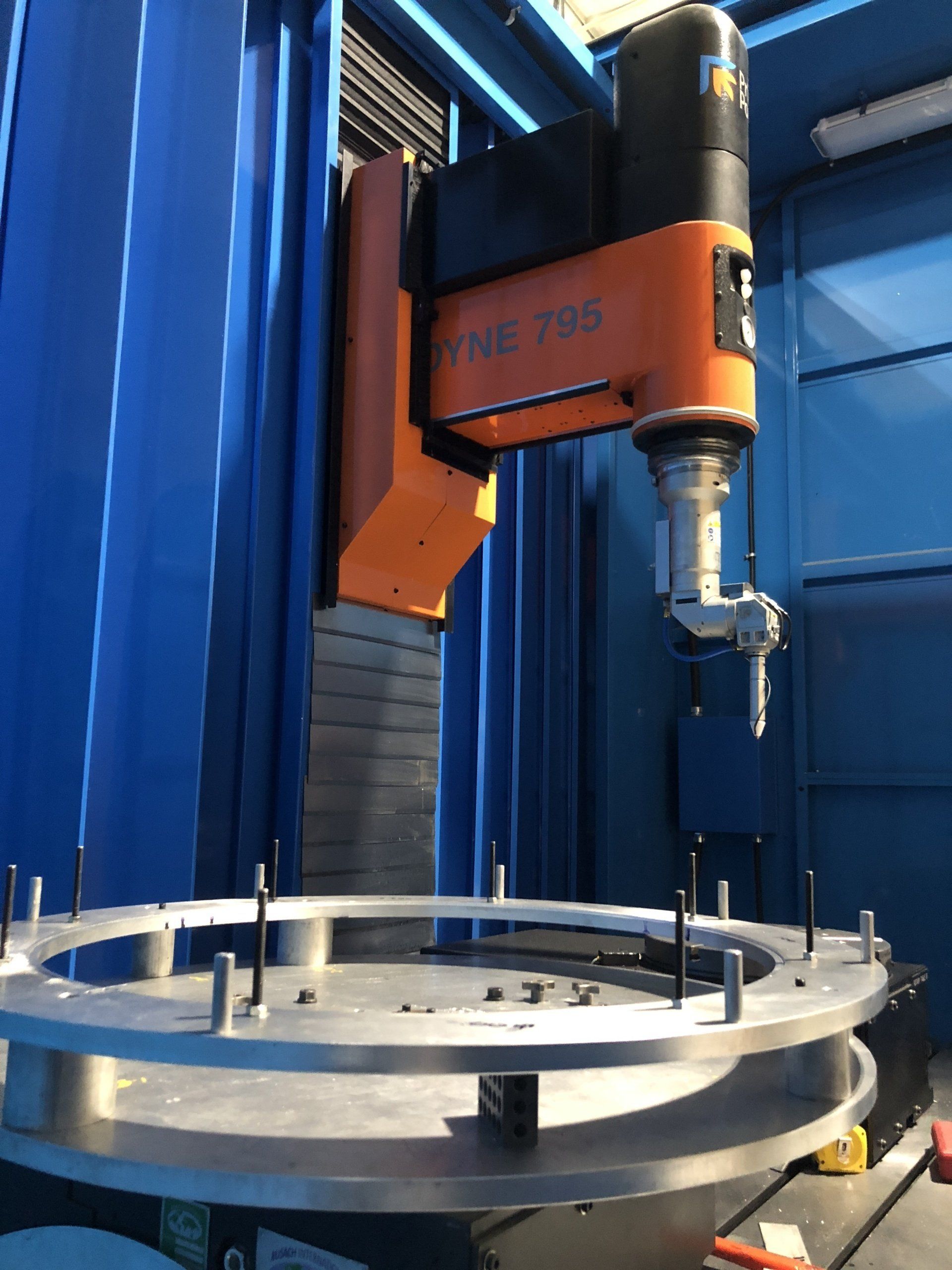

EBTEC operates 15 multi-axis laser machines , capable of handling your precision Laser Cutting needs.

Laser Cutting Services Include:

- Flat sheet cutting

- Extremely sharp edge definition

- 5-axis and 6-axis laser control

- 3D shapes, corners, slots, and holes with high repeatability

- Minimum kerf width

- Ultra-low distortion

- No variations due to tool wear

- Alternative to cutting dies for low-volume production

About Laser Cutting

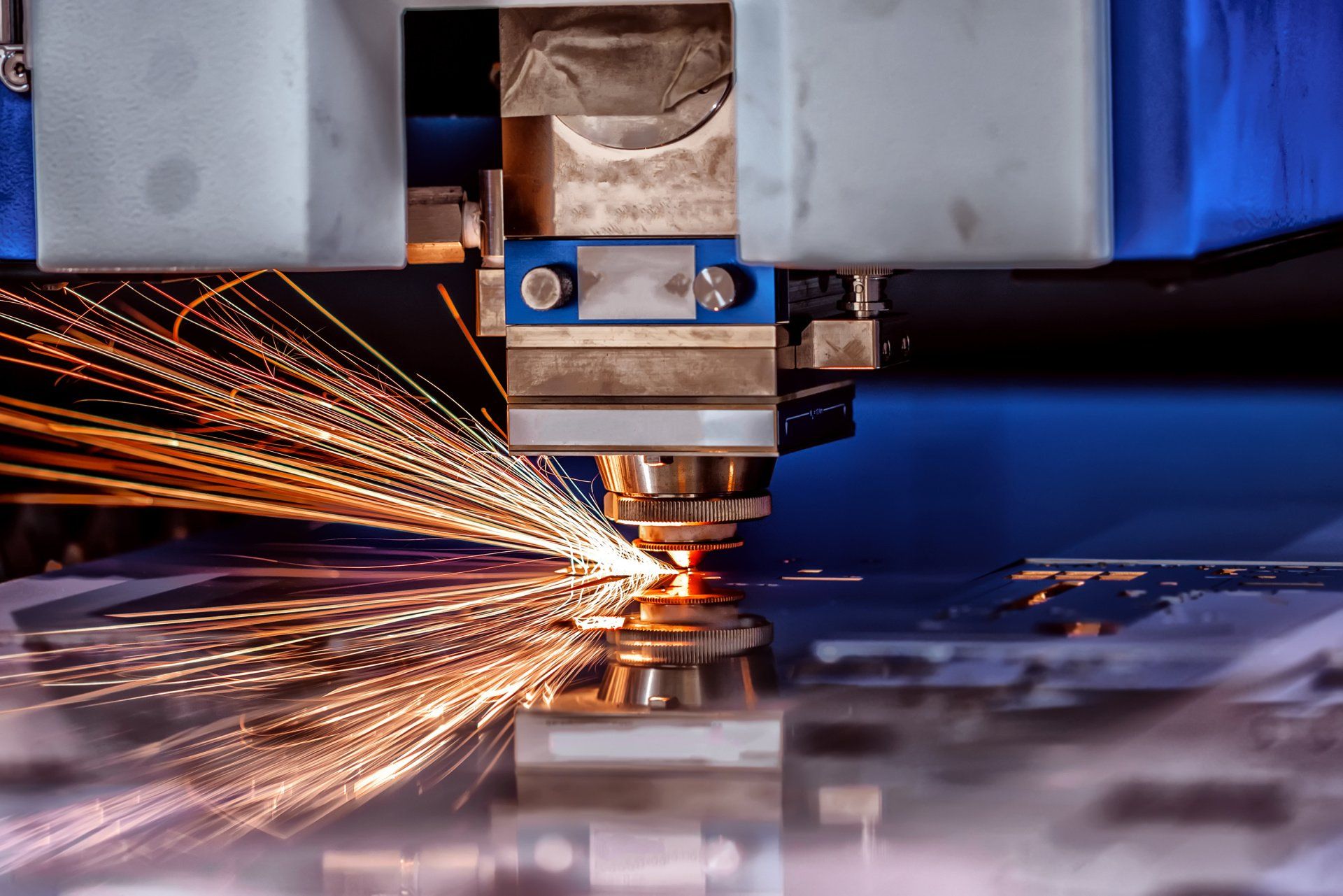

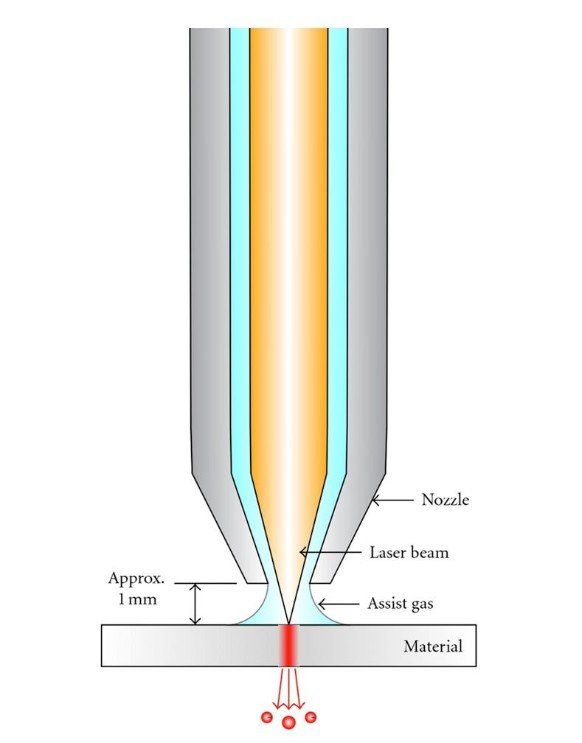

Laser cutting is a thermal process in which a focused laser beam (photons) is used to melt material in an extremely localized area.

The Value of Laser Cutting

Benefits of Laser Cutting Services:

- No cutting lubricants required

- Highly flexible

- No mechanical force on workpiece

- No tool wear

- Very fine cut width

- Narrow heat-affected zone

- Low thermal input

- Highly repeatable

Limitations of Laser Cutting Services:

- Inefficient on high volumes compared to stamping

- Limitations on thickness

- Some metals are suitable

- High capital cost

- Power Consumption is high

- High maintenance cost

- Assist or cover gas required

The Advanced Laser Cutting Process

The Advanced Laser Cutting Process

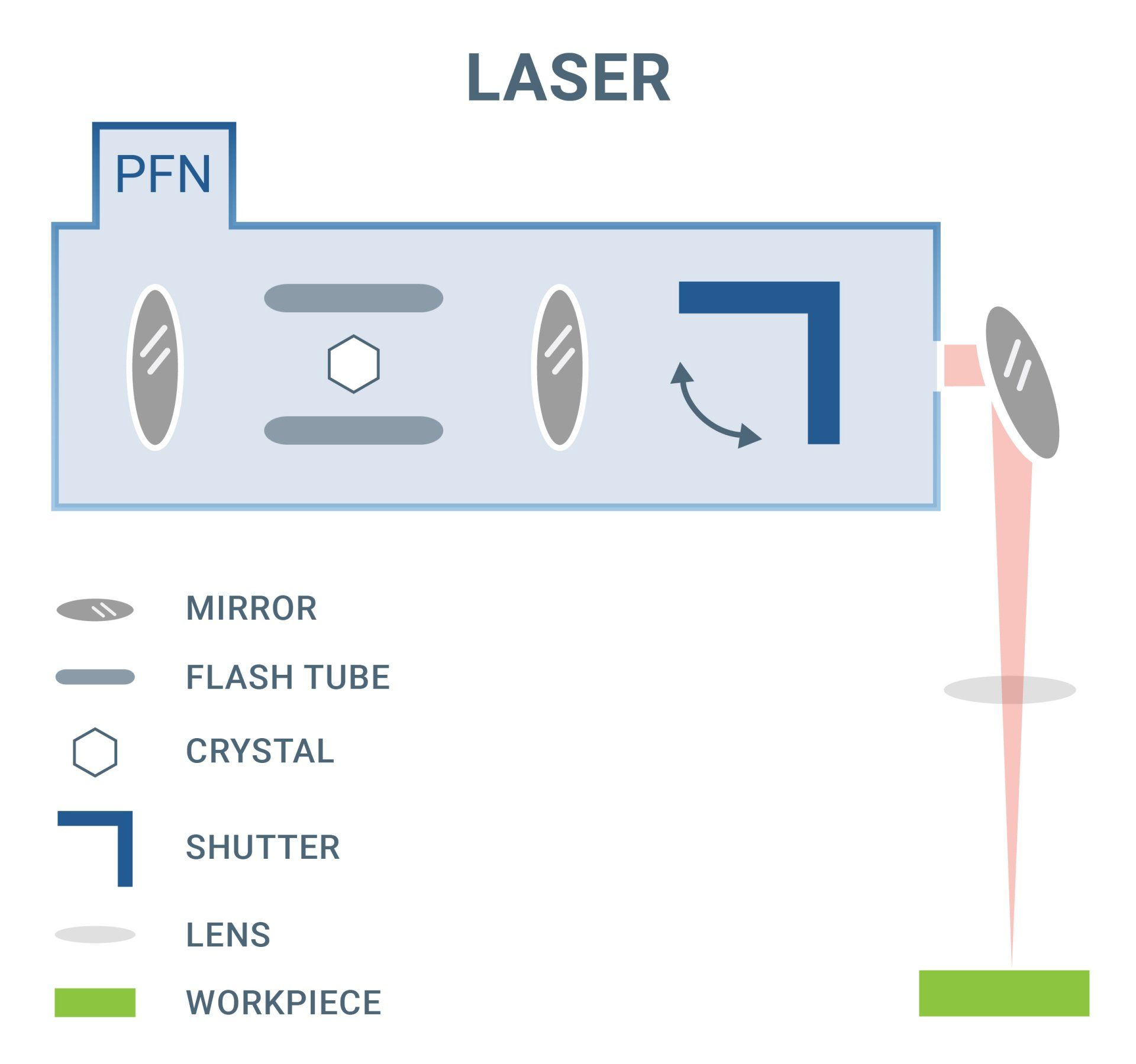

The LASER, an acronym for “Light Amplification by Stimulated Emission of Radiation,” is a device that produces a concentrated, coherent beam of light by stimulating molecular or electronic transitions to lower energy levels, causing the emission of photons. In some of our Laser Cutting equipment, a solid-state laser utilizes a single crystal rod with parallel, flat ends, with each end having reflective surfaces.

A high-intensity light source, surrounds the crystal. When power is supplied by the PFN (pulse-forming network), an intense pulse of light (photons) will be released through one end of the crystal rod. The light being released in our Laser Cutting Services is of single wavelength, thus allowing for minimum divergence.

How it Works

In our advanced Laser Cutting process, 100% of the laser light will be reflected off the rear mirror, and 30 to 50% will pass through the front mirror. The laser light will continue through the shutter assembly to the angled mirror and down through the focusing lens to the workpiece. The laser light beam in our Laser Cutting Service is coherent and has a high energy content. When focused on a surface, laser light creates the heat used for cutting.

The workpiece and the laser beam are manipulated by means of robotics. The laser beam can be adjusted to varying sizes and heat intensity, from .004 to .040 inches. The smaller size is used for cutting, drilling, and welding, and the larger for heat treating.